TubeInspect

Automated tube inspection in high-resolution

The end-to-end solution for tube measurement and production control on the shop floor

Would you like to know more?

TubeInspect comes in two sizes. TubeInspect P8.2 models are fitting with an 8-camera array and are suitable for tubes less than 1000 millimetres long from end-to-end and with a maximum diameter of 125 millimetres. The industrial-sized TubeInspect P16.2 models are fitted with a 16-camera array and can measure tubes up to 7 metres long and with a maximum diameter of 200 millimetres.

Each TubeInspect size comes in a standard model featuring 3-megapixel camera arrays, or an upgraded HRC version outfitted with 12-megapixel cameras.

- TubeInspect P8.2

- TubeInspect P8.2 HRC

- TubeInspect P16.2

- TubeInspect P16.2 HRC

The TubeInspect platform also delivers full automation capability, with high-resolution models ready for complete integration as the quality assurance step within a larger robotic tube production cell. Also delivered with high-resolution models is the possibility to measure end holders and fittings with CAD-Adaptors through image analysis rather than with mechanical adaptors.

3D Hairpin Inspect is a dedicated solution for the high-speed measurement of electric motor hairpins within the production environment. The system supports the full process, including all steps to setup a hairpin production machine.

A specially designed simplified user interface pares down the BendingStudio XT functionality to exactly what is needed during the hairpin production process, making it easy for shop floor users to manage production with minimal training.

Features and benefits

CAD-Adaptors

Asymmetric fittings and holders can be measured without mechanical adaptors, using a digital CAD-Adapter created from a CAD model (IGES, STEP).

Turnkey resilience

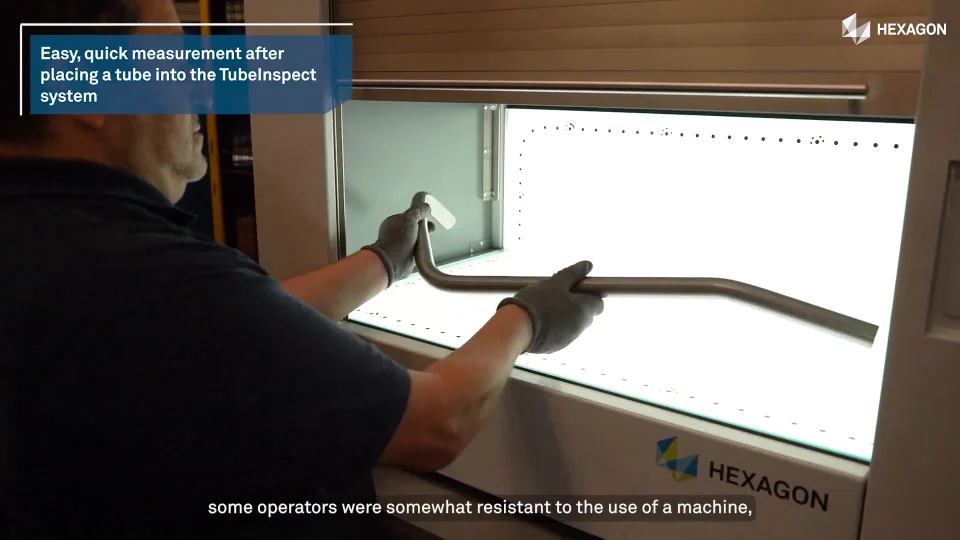

TubeInspect comes in the form of an enclosed concept suitable for rough production environments.

High-speed

Measurement within as little as 3 seconds after placing tube into the measurement system.

Measurement variety

Measure flexible, malleable or freeform bent tubes, either in serial inspection of high-volume batches or for reverse engineering and prototyping applications.

High-resolution cameras

Special HRC models boast an array of 12 megapixel cameras which deliver more detailed inspection functionality as well as powering TubeInspect’s automation capabilities.

Automation ready

Full integration within a larger robot production cell, with external control possible from within a dedicated BendingStudio XT interface.

Direct control

Hotkey button on TubeInspect front panel allows for quickly beginning and confirming measurements, minimising back-and-forth between cell and desktop.

BendingStudio XT software

The well-established BendingStudio XT platform delivers direct bender interfaces for all major brands, measurement plans for rapid batch measurement, automatic and customisable reporting and easy CAD data import and export.

-

Customer stories

General Manufacturing

The digital future of tube manufacturing

Albert Biebl GmbH, Hauzenberg, GermanyGeneral Manufacturing

Harvesting quality

CLAAS Selbstfahrende Erntemaschinen GmbH, Harsewinkel, GermanyGeneral Manufacturing

From minutes to seconds - Increasing tube measurement efficiency

Blomberg & Stensson AB, Katrineholm, SwedenGeneral Manufacturing

Integrated measurement technology for maximum quality

Schmehmann Rohrverformungstechnik GmbH, Bad Marienberg, Germany -

Downloads

TubeInspect and BendingStudio XT for sustainable transportation | Plume Mobility & WTX Europe, France

TubeInspect P8.2 HRC with BendingStudio XT: Fast bender correction on WAFIOS BMF60 for busbar correction

TubeInspect P16.2 HRC and BendingStudio XT: Improving efficiency in tube manufacturing

TubeInspect P8.2 HRC automation: Fully automated tube production-inspection-correction loop

Smart tube manufacturing: Fully automated tube production-inspection-correction

TubeInspect P8.2 HRC: High-speed tube bender correction at Transfluid

BendingStudio XT: The next generation of tube and wire measurement

TubeInspect P16: High-quality analysis of bent tubes and wires